Standards of cashew kernels are built based on AFI standards and ISO standards, shown in the book "Cashew nuts - Production and processing" of author Pham Dinh Thanh, 2003.

For details on the latest cashew standards, please find out more here

General requirements

A. Each shipment to the U. S. shall be inspected or approved by the Federal Bureau of Investigation (FDA) and approved by the Customs Department. Therefore, shipments shall be of good quality and be traded in a fair trade manner.

B. The cashews shall be packed in new, clean, dry, leak-proof containers with an airtight seal and without internal paper liners. Packaging shall be of sufficient strength to assure the integrity of the product during normal shipment and storage.

The outer container shall be constructed of a new cardboard, free of infestation and visual mold and sealed without staples, unless otherwise specified by the end user.

C. Only pesticides approved for use on cashews may be used and residues must be within the tolerances set by the government of the importing country. No detectable residue is permitted for any pesticide that is not approved for use on cashews in the importing country.

D. All cartons shall be clearly marked with the following:

- Name of the product and trade name or brand name, if any.

- Name and address of producer and packer.

- Grade

- Net weight.

- Country of origin.

- Buyer's name or marks.

- Destination.

- Other marks agreed by buyer and seller.

E. Bill of lading must list the number of cartons, source of origin, and the marks that are on the cartons.

F. In order to avoid excessive breakage, it is necessary to check the humidity, storage, packaging and transportation in the most reasonable way. Fluctuations in temperature and humidity shall also be avoided so that the entire product can be protected. During the packaging process, the breakage rate shall not exceed 5% so that in the distribution process, this rate shall not exceed 10%.

G. All shipments shall be inspected prior to loading and shall be carried on conveyances suitable for transporting food products in good condition, i.e. free of odors, insect or mold damage, rodent activity, and all other foreign materials.

H. The moisture level of the cashews shall be 3%-5%.

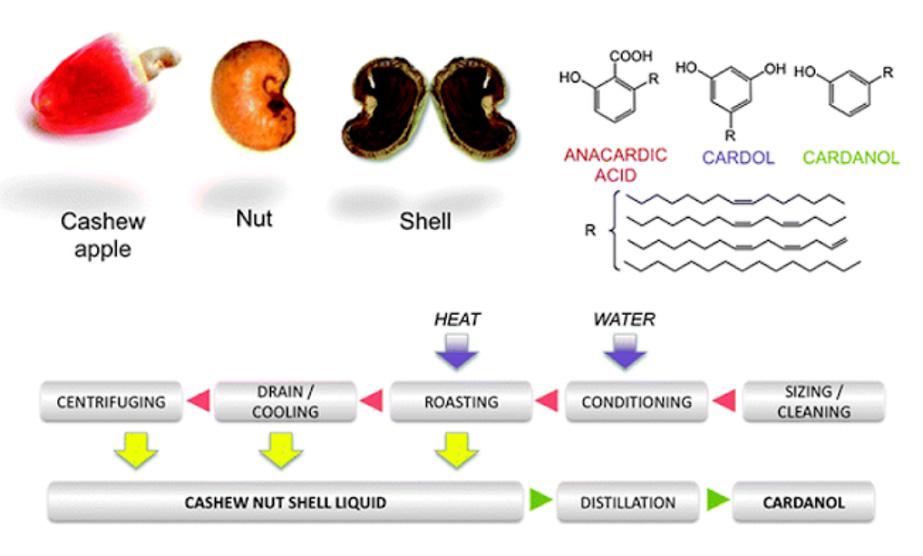

I. In Appendix II, an experiment is introduced on the roasting of cashew kernels

Quality and Grading

Cashew kernels are classified as follows: First Quality Fancy; Second Quality Scorched; Third Quality Special Scorched; Fourth Quality; Dessert.

- First Quality Fancy: Cashew kernels have a uniform color, which may be white, light yellow, pale ivory or light ash-gray.

- Second Quality Scorched: Cashew kernels can be light brown, light ivory, light ash-gray, yellow or dark ivory.

- Third Quality Special Scorched: Cashew kernels may be deep yellow, brown, amber, and light to deep blue. They may be slightly shriveled, immature, defective or otherwise discolored.

- Fourth Quality: Cashew kernels would qualify as First, except that they have pitted spots.

- Dessert: Cashew kernels may be scraped, deeply shriveled, black-speckled, defective or otherwise discolored.

Sizing

Sizing is compulsory in first quality/fancy cashew kernels but is optional for other whole grades.

The quantity of broken kernels or pieces in whole kernels shall not exceed 10% by weight.

The quantity of pieces present in butts and splits shall not exceed 10% by weight.

The quantity of the next lower size grade in pieces shall not exceed 5% by weight.

|

Size Designation |

Count per |

|

|

Kilo |

Pound |

|

|

180 (or SLW) |

266-395 |

140-180 |

|

210 (or LW) |

395-465 |

180-210 |

|

240 |

485-530 |

220-240 |

|

320 |

660-706 |

300-320 |

|

450 |

880-990 |

400-450 |

Whole (W)

A cashew kernel is classified as whole if it has the characteristic shape of a cashew kernel and not more than 1/8th of the kernel has been broken off.

Butts (B)

Kernels which have been broken crosswise are less than 7/8 but not less than 3/8 of a whole kernel and the cotyledons are still naturally attached. This grade may also be designated as B.

Splits (S)

One half of a cashew kernel that has been split lengthwise, provided not more than 1/8 of this cotyledon has been broken off. This grade may also be designated as S.

Pieces (P)

These are fragments of Splits (S) that are provided less than 7/8 of the cotyledon, and shall not pass through a sieve of aperture 4.75mm (US standard No. 7). This grade may also be designated as P.

Small Pieces (SP)

These are fragments of Splits (S) that are provided less than 5/8 of the cotyledon, and shall not pass through a sieve of aperture 2.80mm (US standard No. 7). This type is designated "SP".

Special Small Pieces (SSP)

These are fragments of Splits (S) that are provided less than 5/8 of the cotyledon, and shall not pass through a sieve of aperture 2.36mm (US standard No. 8). This grade may also be designated as SSP.

Crumbs (G)

These are crumbs of Splits (S) and shall not pass through a sieve of aperture 1.70mm (US standard No. 12). This grade may also be designated as G.

Definitions

ADHERING MATTER - cashew meal or extraneous matter on the

surface of the kernel causing permanent discoloration.

Serious damage includes but is not limited to insect, rodent or bird damage, visible mold – rancidity – decay or adhering dirt – solder – shell – or mesocarp.

Insect damage - is visible damage to the kernel from live or dead insects, mites in any stage of development, insect excreta or fragments – frass – webbing – boring – powdery residue – cast larval casings and/or the evidence of insects or insect activity in the packaging.

Rodent damage – evidence of rodent activity.

Bird damage – pieces of feathers, bird excreta.

Visible mold – mold filaments detectable with the naked eye.

Rancidity – is a breakdown of the oils in the cashew kernel.

Rotted kernel: any decay that is larger than 1mm in radius or penetrates 1mm or more into the nut is considered a decayed nut.

Foreign matter – includes but is not limited to shell, mesocarp, stones, dirt, glass, metal, solder, straw, twigs, sticks, plastic, hair, industrial fibers, paper and threads.

Defects include superficial and intrinsic damage which adversely affects the appearance of the lot such as scorching, blemishes, discoloration, immature or shriveled kernels, kernels with pitted black or brown spots, adhering testa, scrapes, flux marks and speckles. Defects vary by grade. The presence of kernels of a lower grade is scored as a defect. Examples of defects include:

Scorching – a discoloration due to overheating during shelling or blanching.

Blemishes or Discoloration – spots in aggregate in excess of 3 mm on the kernels from causes other than shelling or blanching.

Immature – kernels are underdeveloped and do not have the characteristic shape of a cashew kernel.

Slightly shriveled – a slight withering of the outer surface of the kernel.

Shriveled – a complete withering of the kernel that distorts its characteristic shape.

Pitted spots – black, brown or other colored spots in aggregate in excess of 1 mm caused by pre-harvest attack on the kernel.

Adhering testa - Kernels are scored as affected by adhering testa when a surface area greater than 2mm in aggregate is affected.

Superficial damage – deep knife cuts on the surface of the kernel that change the characteristic shape of the nut.

Flux marks – black or brown marks on the surface of the kernels caused by flux dripping onto them when a tin container is sealed.

Speckled – a brown stain which appears after removal of the testa on some kernels.

Tolerances for Defects and Damage in Cashew Kernels

The following tolerances establish the maximum limits for damage and defects in raw cashew kernels. To determine compliance with these tolerances, one should follow the Sampling Plan found in Appendix I, and use established analytical procedures. Tolerances for a lower grade include the kernels defined by the lower grade but not the defects that are specific to the lower grade. Percentages are determined by weight.

|

|

First Quality |

Second Quality |

Third Quality |

Fourth Quality |

Fifth Quality |

|

Serious Damage |

|||||

|

Insect Damage |

0.50% |

1.0% |

1.0% |

1.0% |

1.0% |

|

Mold rancidity, decay, adhering matter |

0.50% |

1.0% |

1.0% |

1.0% |

1.0% |

|

Foreign Matter (1) |

0.05% |

0.05% |

0.05% |

0.05% |

0.05% |

|

Maximum Serious Damage |

1.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

Defects |

|

|

|||

|

Second Quality Scorched |

5% |

- |

- |

5% |

- |

|

Third Quality Special Scorched |

1.50% |

5% |

- |

2% |

- |

|

Fourth Quality |

5% |

1% (2) |

2% (2) |

- |

- (3) |

|

Blemished Wholes |

0.50% |

2.5% (2) |

7.5% (2) |

2.5% (4) |

- (5) |

|

Superficial Damage (scrapes) |

1% |

2% |

5% |

1% |

- |

|

Adhering Testa/Seriously Damaged (6) |

1% |

1.50% |

1.50% |

1.50% |

5% |

|

Maximum Defect Level |

8% |

10% |

10% |

10% |

- |

- The tolerance for foreign matter is in addition to the tolerance for maximum serious damage.

- The combined tolerance of Fourth Quality and Blemished Wholes does not exceed the tolerance of Blemished Wholes.

- Fourth Quality allows black or brown, other colored spots.

- This tolerance is for one or more dark spots on one or both sides of the kernel.

(5) Blemished Wholes is the lowest class. However, if there are too many defects, the goods will not be sold. It is still acceptable as long as the quality is better than the offered sample or these pre-offering samples are sent to the customer 1 sample, the other sample is retained by the arbitrator for arbitration in the event of a dispute.

(6) Cashew kernels with testa skin that are larger than 3mm in diameter adhered to the kernels are counted twice as % of the silk shells.

Appendix I

|

Sampling Plan for Cashews |

||

|

Lot size |

Number of cartons sampled |

|

|

Number of cartons |

Normal |

Detail |

|

50 |

3 |

7 |

|

51-100 |

6 |

10 |

|

101-200 |

6 |

14 |

|

201-350 |

6 |

18 |

|

351-400 |

13 |

20 |

|

401-500 |

13 |

22 |

|

501-700 |

13 |

26 |

The sampling plan is intended to encourage homogenous sampling. Test samples to determine correlation with product standards.

Sample weight of approximately 500 g/(1 sample) is taken at random from the lot. Multiple subsamples combined into one 1000g test sample for analysis. However, these samples will be analyzed individually if required.

The usual procedural sampling plan used for the first inspection of the incoming consignment. This plan is also used when testing for factors other than insects is required.

The subsample analysis must be carried out under spectral light conditions with full CRI chromatic return criteria not less than CRI 91.

Appendix II - Roasted Cashew Kernels

Almost all cashew kernels are sold to the consumer in the US after roasting. The appearance of the roasted kernel is critical for consumer acceptance. It is therefore recommended that shippers roast cashew samples prior to packing to determine the appearance that a lot will have after roasting. This is simply good manufacturing practices.

The roast test also confirms the proper classification of a lot, as to whether it should be sold as first, second, or third quality.

The roast test shall also be of acceptable quality, i.e. a percentage of poor quality not exceeding 5% (speckled nuts, discolored nuts, discolored nuts, deep color).

Roasting procedure:

The kernels should be roasted in a clear vegetable oil for 3 minutes. The oil is brought to a temperature of 300 – 310F (154C). Let the nuts cool before checking.

Defects:

The kernel with brown spots

Scorched tip – a tip that is significantly darker than the remainder of the kernel due to a scorching during shelling or blanching.

Color Variation – any discoloration, other than a scorch mark, which detracts from the uniform appearance of the kernel.

Dark roast – a light to medium brown color in some kernels that detracts from the uniform appearance of kernels that are significantly lighter.

Scrapes – knife scratches greater than 5mm in diameter that show up as light spots on the surface of the kernel.

Uneven roast - roast with more than 7% total of the following defects: spotted, scorched tips/color variations, deeply scorched tips, dark roast, and deep roast.

Maximum Tolerances for Defects in First and Second Quality Roasted Cashew Kernels

|

|

First Quality |

Second Quality |

|

Spotted |

1.00% |

2.50% |

|

Scorched Tips/Color Variations |

2.00% |

No limit |

|

Deeply Scorched Tips |

1.00% |

2.50% |

|

Dark Roast |

5.00% |

No limit |

|

Deep Roast |

2.00% |

10.00% |

|

Scrapes |

5.00% |

No limit |

.

*The total Defect Level for First Quality cannot exceed 7% for defects.

REFERENCE

Thanh, D. P. (2003). Cashew nuts - Production and Processing.