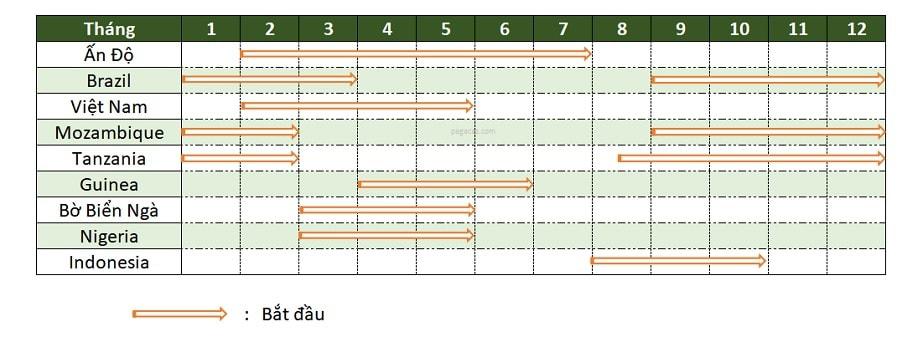

As known, cashew fruits ripen and are harvested normally at the beginning of the dry season or at the end of the cold season. Because the botanical and morphological characteristics of the cashew tree are not favorable for mechanization, cashews are often harvested mainly by hand, not by machines.

Harvest

In an inflorescence of the cashew plant, there can be flowers, freshly formed fruits at different development stages and ripe fruits at the same time. Besides, different trees also have a variety of canopy shapes. Cashew fruits do not ripen at the same time. Therefore, cashew harvesting can last up to 4-5 months. However, the peaking time of harvesting is only in the first 12 weeks of the harvest season.

During harvesting, it is necessary to only harvest fully ripe fruit to ensure the quality of the product. When cashew apples become ripe morphologically, their outside color has turned red or yellow (depending on the variety). At this time, the fruit has the lowest astringency, its flesh is soft, succulent, sweet, and has a characteristic aromatic similar to that of strawberries. For cashew nuts, the sign of ripeness is when the green color of the nut changes to gray-brown.

Fig.1 - Cashew harvest season in some countries (Thanh P. D., 2003)

Preliminary processing

Depending on production requirements, if it is necessary to harvest both cashew nuts and apples, the harvesting can be done right on the tree. When picked, the cashew nut and apple are separated for further processing. The fruit needs to be used immediately because it is very susceptible to damage (rotting) due to the first dangerous fermentations appearing in the cashew apple within 24 - 36 hours after harvesting. That is also why it is limited and difficult to use and transport cashew apples long distances. If it is not necessary to harvest the cashew apple, wait for the ripe fruit to fall to the ground and then collect it periodically if it does not rain or collect it every day if it rains.

Dry cashew nuts

When collecting cashew apples, cashew nuts must be separated from the fruit. The nuts must be de-stemmed and cleaned of sand so as not to hinder size classification during processing. After that, the fresh nuts must be dried in the sun for 2-3 days or longer if necessary, which helps reduce the moisture content of cashew nuts from 15 - 17% when newly picked to 9% or less. This initial processing is very important both technically and economically. Because cashew nuts are a seasonally harvested material for storage and production all year round, the cashew nuts with high moisture content are susceptible to mold, bacteria or enzymes when stored in the warehouse. This will impact on the quality of cashew kernels because of hydrophobicity of fats (38 - 47%) contained in cashew nuts. The most obvious damage is that the whiteness of the kernel will gradually turn yellow over time in storage. In the experience of many processing factories, if the nuts are well dried, the percentage of white kernels obtained through processing can be 10% higher than with poorly dried seeds. The export price of yellow cashew kernels decreased by 20 - 30% compared to white kernels of the same level.

Fig.2 - A corner of the cashew drying yard in Pagacas

It should be noted that the drying yard must be smooth and sloped to ensure that there won’t be rainwater stagnation. When drying, spread the nuts into a thin layer no more than 10 cm thick (the thinner the better), and always stir them evenly (use a wooden tool to stir the nuts during the drying process so that the cashews dry evenly, facilitating the processing process). When achieved a proper dryness of 9% or less, nuts must be cooled to room temperature before being packed into sackcloths and put into storage. If the nuts are still hot when packaged, they will be susceptible to late blight during storage. In case it rains and cannot be dried immediately, cashew nuts stored indoors must be spread thinly (if possible) in a well-ventilated place or use a fan to blow air and must always be turned, otherwise the young seeds will damaged, organic impurities deep inside nuts are often major sources of causing heating, reducing the quality of the nuts. When the sun dawns, take the nuts out to dry until they reach the proper dryness.

Standards for raw cashews material

Because there has still not been a standard quality grading scale as a basis for pricing in trading raw cashews material, trading these raw nuts is more complicated than trading cashew kernels.

Each region that produces cashew nuts in each country develops its own cashew quality standards for trading. Build quality requirements for raw cashew nuts bases on some following characteristics:

- The moisture content of cashew nuts

- Percentage of nuts that are flat or have no kernel, and nuts that are rotten and crushed

- Number of nuts/1 kg of nuts

- Impurities, sand, soil, sticks, etc.

For example, in Mozambique, cashew quality requirements are regulated as follows:

- The maximum moisture is 8%. Exceeding 1% of moisture, the price will be reduced by 1%, above 12% of moisture can be rejected.

- The rate of all types of damaged nuts is up to 10%, exceeding 1% of damage rate, the price will be reduced by 1% or be refused to buy. The damage rate is lower than the prescribed 1%, the price will be increased by 0.5%.

- Allowed impurities are 1%, if exceeding 1%, the price will be reduced by 3% and for every 1% lower, the price will be increased by 0.5%.

In Tanzania, people only classify the quality of cashew nuts into two levels: standard cashew nuts and non-standard cashew nuts.

- Standard cashew nuts: Cashew nuts contain impurities below 0.25%. The rate of flat, damaged nuts or nuts from the old season is below 13%.

- Non-standard cashew nuts are nuts that do not meet the above requirements.

With this grading method, Tanzania's cashew nut output is estimated to reach the standard of about 80%.

In India, depending on the region or state, there are different cashew quality regulations.

|

Grade |

Special features |

|||||

|

Impurities (max) |

Moisture content (max) |

Number of nuts/kg |

Empty nuts (max) |

Young nuts (max) |

Damaged nuts (max) |

|

|

Especial |

0.25% |

12% |

160 |

1 |

1 |

2 |

|

Good |

0.25% |

12% |

180 |

2 |

2 |

3 |

|

Quite good |

0.25% |

12% |

210 |

3 |

3 |

4 |

Table - Regulations on grades of cashew nuts (In North and South Kanara regions, Kanataka state).

|

Grade |

Special features |

|||||

|

Impurities (max) |

Moisture content (max) |

Number of nuts/kg |

Empty nuts (max) |

Young nuts (max) |

Damaged nuts (max) |

|

|

> Especial |

- |

12% |

100 |

- |

- |

- |

|

Especial |

0.25% |

12% |

150 |

1 |

2 |

2 |

|

Good |

0.25% |

12% |

160 |

2 |

3 |

3 |

|

Quite good |

0.25% |

12% |

210 |

3 |

4.5 |

4.5 |

Table - Regulations on grades of cashew nuts (In the Konkan and Malaba coasts, Karala state)

General features:

Ripe cashew nuts collected from Anacardium occidentale L. cashew trees grown in North and South Kanara, Malaba and Konkan seas, have been dried and have some following features:

- Shape, color and other features of the breed.

- The nuts are fully ripe and thoroughly dried.

- No musty smell.

- There are no molds, diseases, crushed seeds, seed-destroying insects, etc.

- Empty nuts: nuts without a kernel.

- Unripe nuts (immature): nuts with wrinkle kernels.

- Damaged nuts: nuts infected with pests, seeds containing discolored kernels.

- Impurities: includes soil, rocks, dirt, dried cashew pieces, leaves, etc.

Fig.3 - Raw cashew nut standard

Specific indicators on the quality of purchasing and preliminary processing of raw cashew nuts are prescribed as follows:

- Humidity:

Moisture content of fresh ripe nuts measured by a specialized meter:

- February & March: 18% or less

- April & May: 20% or less

Do not buy young nuts with green skin, green spots, or nuts that have been soaked in water.

- Shrunken, rotten nuts, nuts that are not ripe enough:

Shredded nuts: the nuts without a kernel or with a kernel but < 75% of the kernel.

Worm nuts: cashew nuts’ kernels that have been damaged by insects or worms.

* Black, shriveled, decayed nuts (< 5% of the nut).

Nuts that are not ripe enough: nuts that are still green when picked. Although the nut shell has turned gray, the water content in the shell and kernel is still high, and the moisture content when fresh is > 20%.

* Nuts are not ripe enough to be 12% or less.

- Nut size:

Based on the weight of fresh seeds, they are divided into the following three types:

- Large type: number of nuts/kg 170 or less

- Medium type: number of nuts/kg from 170 - 190

- Small type: number of nuts/kg from 190 - 210

Handling improper ratios:

- If the moisture content exceeds the specified limit, 1% of the weight will be deducted for every 1%.

For example, if the humidity is 20%, the weight will be deducted according to the excess ratio.

- If the rate of rotten or shriveled nuts exceeds the specified limit, for every 1% excess, 1% will be deducted by weight.

- In terms of the percentage of nuts that is not ripe enough, subtract 0.5% of the weight for each 1% excess.

Quality standards after drying and preliminary processing for storage:

- 10% or less of humidity (measured when cool).

- Not fully ripe nuts are 3% or less.

- No impurities such as sandy soil, young and rotten nuts must also be removed.

How to process cashew nuts

(according to old oiling method and new steaming method)

Cashew processing is carrying out segments of production to obtain cashew kernels. Cashew kernels that are processed must be ensured to not be broken, not get dirty oil shells and to retain their natural white color.

Cashew processing can be done by manual, mechanical or automatic methods. The cashew processing process consists of the following steps:

- Washing off sandy soils stuck to the nuts.

- Sizing into 3 types: large, medium and small for the purpose of processing properly.

- Moisturizing nuts means increasing the initial humidity from 10% or less to 15 - 20%. Or in other words, moisturizing is supplying water to the nuts. Because of the water, the oil can easily escape, causing the shell to swell and be easier to be peeled. Cashew kernels, therefore, will not be scorched and broken during oiling.

There are many ways to moisture such as regularly watering the containing bag, soaking nuts into water or steaming nuts. The water for moisturizing must be clean, especially iron-free, and the water temperature must not exceed 30 degrees Celsius. Be careful not to let too much water seep through the testa skin, which discolors the kernel.

- After moisturizing, heat treatment is carried out to swell the nut shell for the purpose of peeling easily. Roasting directly over fire or roasting in cashew shell oil at a temperature of 180 - 200 degrees Celsius are two widely-used methods of heat treatment. In terms of roasting in oil (oiling skimming), the kernels retain their color and have good quality. In addition, so far, steaming in a high temperature of 100 - 170 degrees Celsius is still used. This method also swells the shell, but the gap between the shell and kernel is smaller than that caused by the oiling method, which makes it more difficult to peel.

Nowadays, heat treatment is commonly done by steaming method, oiling and direct roasting are almost no longer applied.

- After heat treatment to swell the shell, the shell will be shelled. Then, cool the shell quickly to normal temperature, which makes peeling easier due to the hardness of the nut shell, avoiding to break or damage the kernel during shelling. People often use a tool with 2 blades shaped upon the size of cashew nuts to cut and peel the shell. If the nut is larger or smaller than the knife distance, it will easily be broken. Therefore, accurate sizing is very important. The widely-used equipment for sizing in the cashew processing industry is a rotary drum screen machine.

In addition to shelling with mechanical equipment, the shell can also be peeled manually by gently tapping the nuts with a hammer, taking care not to break the kernels. In India, Labor productivity in 8 working hours is 7-10 kg of kernels, the rate of whole kernels is over 90%. Use rubber gloves to protect your skin and keep the kernels clean during shelling.

- After shelling, the cashew kernel continues to be dried to dry the kernel and reduce the adhesion of the testa to the kernel, which makes it easier to get the kernel out of the testa skin. The temperature in the drying chamber needs to be kept stable at 70 - 80 degrees Celsius during drying. Stop drying when the moisture of kernels reaches 2.5% - 3.5%. Borma, a type of dryer that uses convection heat to dry cashew kernels, was used widely before. However, using a Borma dryer is labor-intensive because it must change the position of the trays in the dryer room for every 10 - 30 minutes to dry cashew kernels evenly while the quality of the dried kernels is not high, and the drying time is 10 - 12 hours long. Currently, a hot-air forced circulation drying oven heated by electricity, firewood or hot steam is often used. Using this new type of drying oven has a relatively stable temperature, short drying time (from 2 - 4 hours), moderate cost, and helps obtain good kernel quality.

- After being dried according to certain requirements, cashew kernels (with testa skin) will be transferred to peel the testa skin. There are two common methods of peeling testa skin: manual peeling and mechanical peeling. The most important thing is to ensure a low breakage rate and a prescribed peeling rate.

In the period before 2005, peeling testa was done mostly by hand. Although the increase in labor productivity was low, the breakage rate was low (about 8-10%). Although mechanical peeling has high productivity, the rate of broken kernels is quite high, in addition, the rate of missing kernels is also over 20%, leading to poor efficiency.

- The next stage is classifying products from cashew kernels. Classification standards are based on natural color and breakage rate of kernels. Cashew kernels can be divided into 4 or 5 types, of which type 1 has the highest quality, uniform color, no scorched, broken kernel rate < 10%. In addition, pay attention to food hygiene and safety requirements such as no pesticide residues, no Aflatoxin toxins and no contamination with bacteria that cause disease in humans. To ensure the above requirements, both growers and processors must comply with food hygiene and safety regulations.

- Finally, in terms of packaging, packaging bags can be different in size but must be sealed, dry and clean. Most often, use tin containers or aluminum foil bags, plastic bags stored in cardboard boxes.

Processing cashew apples

Cashew nuts are processed into drinks, candy, jam, canned cashew apples and cashew wine.

Drinks made from cashew apples are mainly juice and syrup. Choose newly picked cashew nuts that are fresh and intact and put them in the juicer. Choose newly picked cashew nuts that are fresh and intact and put them in the juicer. Cashew juice is de-astringent, then mixed with the juice of some other fruits such as lemon, pineapple, grape or apple to create very fragrant and delicious carbonated drinks.

Fig.4 - Ripe cashew apples are harvested

To prepare cashew syrup, add lemon juice and an appropriate amount of sugar so that the juice has a concentration of 35 degrees Brix. Cashew syrup when used is diluted as required.

Cashew juice is also concentrated at a temperature of 50 - 55 degrees Celsius in a vacuum, resulting in concentrated cashew juice above 35 degrees, possibly even up to 65 - 75 degrees Brix, from which makes carbonated drinks that are very good for health.

To prepare cashew candy and jam, the process is similar to that of other fruits. In Brazil, people make up to 5 types of candy and jam from cashew apples, which are very popular.

Canned cashews are often packed with pineapple in a 1:1 ratio to make a delicious dish. Green cashew fruits are also good for making pickles.

Cashew fruit juice is fermented to make wine and liquor with high alcohol content, the quality of which is not inferior to domestic wines such as whiskey and rum.

Processing cashew nut shell oil

Cashew shells contain a reddish-brown liquid called natural cashew shell oil (CNSL). It is a mixture of alkyl phenols such as anacardic acid and cardol that can blister human skin.

When processing cashew nuts using the oiling method at high temperatures above 100 degrees Celsius, the above substances are converted into technical cashew shell oil (or commercial cashew shell oil). Cashew nut shell oil, after being detoxified with sulfuric acid, is used as a raw material to make paint, varnish, glue, plastics, rubber compounds, etc.

With the uses of cashew fruits, especially cashew nuts and kernels, the cashew tree has become an industrial crop with high economic value. The world demand for cashew kernels is increasing day by day. With suitable natural conditions, cashew farming in our country is developing rapidly, possibly making our country one of the countries that produces, processes, and exports the most cashew nuts in the world.

REFERENCE:

Thanh P. D. Cashew nuts - Production and Processing (2003).