After being graded properly (dry enough: humidity < 5%), cashew kernels are packed in tin boxes (a type of standard packaging has been accepted by the market for decades). Each box contains a net weight of 25lb (1lb = 0.4534kg). These boxes are vacuum sealed and filled with CO2 inert gas and then sealed. Two tin boxes are put into one carton and then put in the warehouse waiting to be loaded onto the export ship.

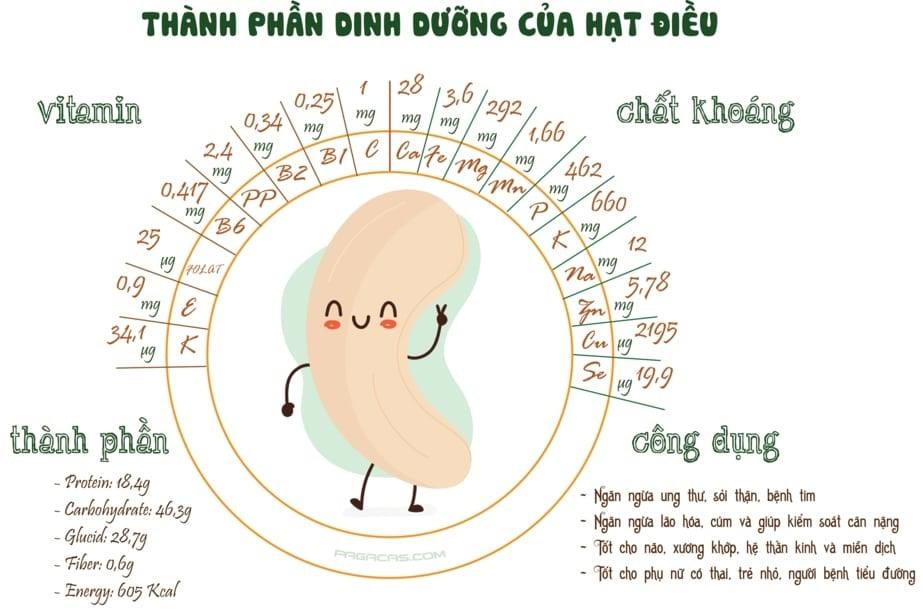

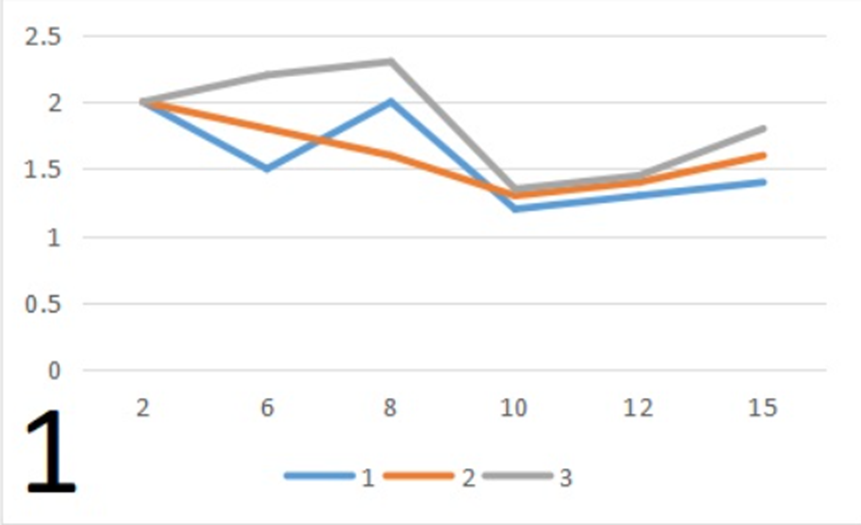

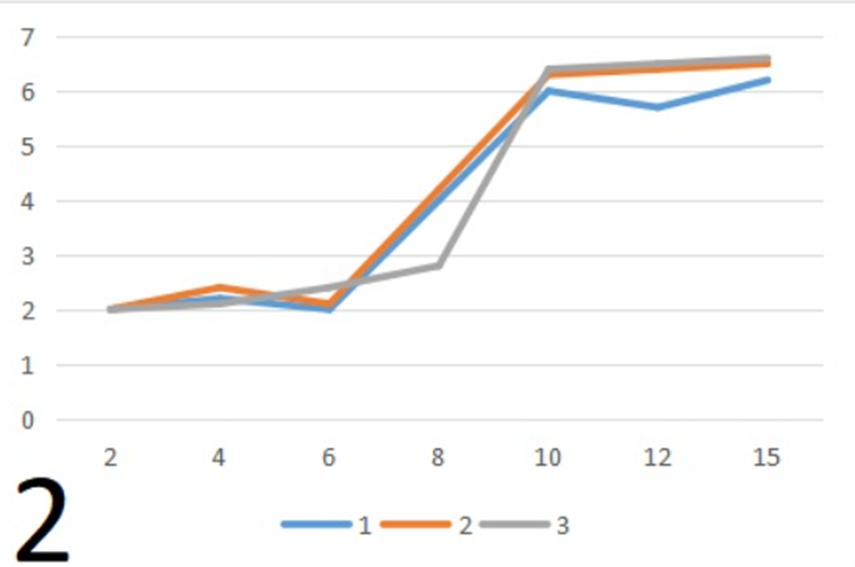

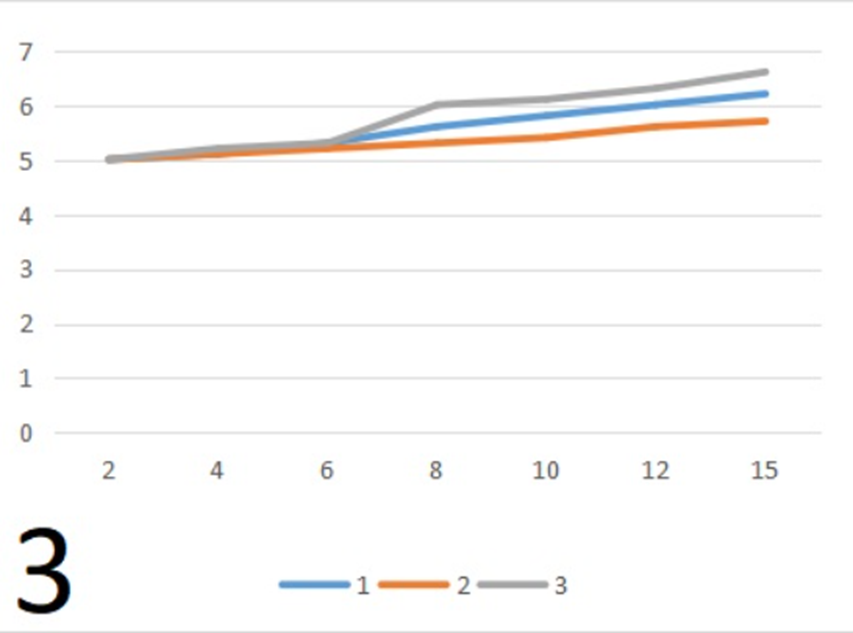

When investigating physical-chemical transformations of cashew kernels during storage at room temperature (16 - 30 degrees Celsius) and at frequent high temperature conditions (37 degrees Celsius), S.Shivashankar, A.G. Mathew and C.P. Natarajan (1974) (Figures 49 and 50) showed that at room temperature after 15 months of storage, moisture content increased slightly by 0.9 to 1.5%, free fatty acids (% oleic acid per fat) were 0.49 to 0.53% and the peroxide value (milligrams equivalent/1000 grams of fat) is 1.24 to 1.6. Cashew kernels show no signs of rancidity even though the humidity exceeds 5%.

Changes in moisture content, free fatty acids and peroxidation values at room temperature:

Figure 1 - Peroxide value meq/1000g fat

Figure 2 - Free fatty acids (% oleic acid in fat)

Figure 3 - Humidity (%)

- Control sample (cashew kernel); 2. Cashew kernel with CO2 gas; 3. Cashew kernel with BHA 0.02%/ fat content.

These results show that cashew kernels with good quality, less than 5% humidity and stored at room temperature over 1 year are not damaged even in the absence of CO2. However, during the packaging process, the presence of CO2 gas is indispensable to prevent the destruction of insects (including ants) during storage and loading onto the export ship or (although very rare) the presence of insect eggs in the product when packaged. According to a survey by Oltremare (Italy), the CO2 gas loaded into the bag of cashew kernels has killed off all bacteria and insects after 24 hours of packaging, then the water and fatty acids contained in the cashew kernel's composition will be absorbed up to 80% of this CO2 in the first 48 hours after packaging.

Many studies have indicated that the presence of heavy metals such as lead, calmium, mercury, hexavalent chromium in food packaging is harmful to human health (directly when these metals adhere to food and indirectly when these packages are released and buried on the ground, they will pollute the air and soil environment), so many countries have very strict regulations on the levels of allowed heavy metals used for food packaging. For example, the United States, the world's largest importer of cashew kernels, has set forth specific regulations on the allowable levels of the total content of heavy metals in food packaging as follows:

- After January 1, 1993, do not exceed 0.06% of the weight of the package.

- After January 1, 1994, do not exceed 0.025%.

- After January 1, 1995, the level must not exceed 0.01%.

(Richard Sulivan, President AFI, USA)

With this new regulation, tin boxes that use leaded solder tin are no longer suitable for storing cashew kernels. Instead, other materials can be used to package. In India, cashew kernels are put in paper bags made of aluminum > 0.2 mm thick. This paper bag includes 3 layers: The outermost layer is paper used to print labels, the middle layer is aluminum foil, and the innermost layer is polyethylene plastic to seal when hot pressing the mouth of the bag. This type of bag keeps CO2 from escaping and stays the product safe for 6 months. After packaging, each bag is placed in 1 carton and then 2 cartons are placed in a wooden crate to prevent mechanical collision that causes breakage of the kernel. Besides, plastic boxes have also been considered and studied as a new packaging method to pack cashew labels (the same as traditional tin boxes).

Oltremare (Italy) has also introduced and provided processors to bags with a 3-layer structure: the outermost layer is a 50 micron thick polyamide plastic layer, the middle layer is polyurethane plastic layer 3 microns thick, and the innermost layer is a 150 micron thick polyethylene resin with 5% E.V.A.. The total thickness of 3 layers is 0.203 mm. The 535 x 919 mm bag packs a net weight of 50 pounds of cashew kernels. When packing, ensure:

- The bag is vacuumed to have a vacuum of 20% (20 Mbar pressure).

- Then fill the bag with an inert gas mixture consisting of 20 - 30% CO2 and 70 - 80% N2 gas.

+ CO2 will promote anti-bacterial and insect destructive effects in the first 48 hours after packaging and then be absorbed mostly by the kernel.

+ N2 gas is not absorbed, this inert has the effect of preventing oxidation and other chemical reactions while maintaining the pressure inside the bag against the effect of external pressure, keeping cashew kernels no clumping when using plastic packaging.

- Finally, seal the mouth of the bag.

Each finished bag is placed in a carton with dimensions of 630 x 325 x 190 mm. A 20' container can hold at least 700 cartons.

REFERENCE

Thanh D. P. (2003). Cashew Nuts - Production and Processing.